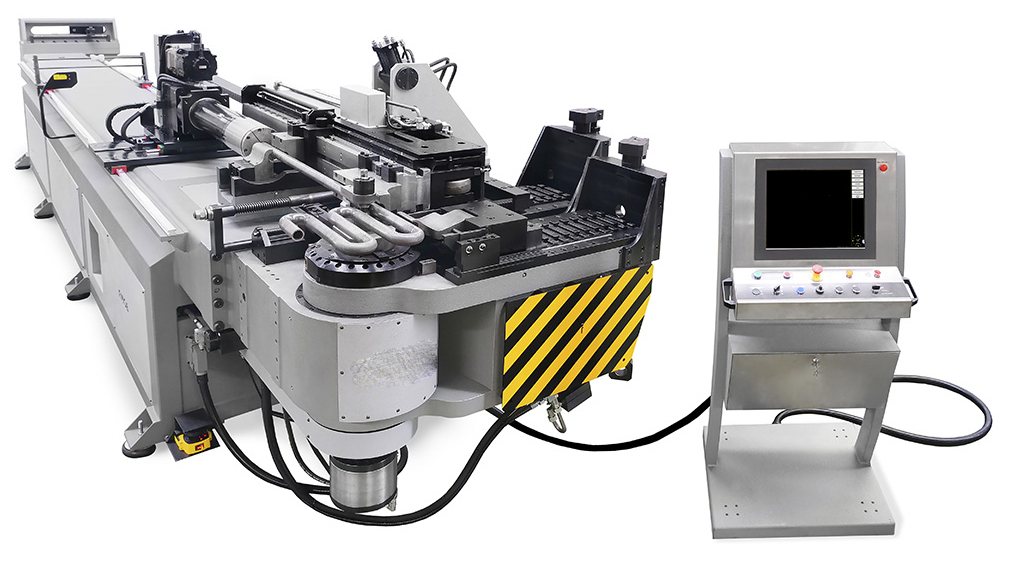

We offers Computer Numeric Controlled (CNC) pipe bending services for larger bends and for customers requesting high-quantity tube and pipe bending services. We have the ability to work with copper, brass, aluminum and stainless steel.

We offers Computer Numeric Controlled (CNC) pipe bending services for larger bends and for customers requesting high-quantity tube and pipe bending services. We have the ability to work with copper, brass, aluminum and stainless steel.

Our highly-trained bend technicians are capable of CNC bending a wide range of bend radii. Our experts have many years of experience and knowledge, which allows them to provide the most accurate bends possible.

Automatic Conversion: The machine can also perform part simulation and automatic conversion from X-Y-Z coordinate data to Y-B-C (Bend Program) working datum, or vice versa. STEP and IGIS files can also be imported directly into the control to allow for an easy, one-step process for programming and setup.

Precise Bending Capabilities: Our CNC tube bender uses the latest software technology and hardware available. A PC based computer system utilizing BendPro software, enables Axenics CNC tube bender to perform difficult sweep bending anywhere along the tube geometry. The possibility of defects in your piping kits is greatly diminished using this method, plus, by not having welds or joints as part of the finished piping, leaks are not a problem.

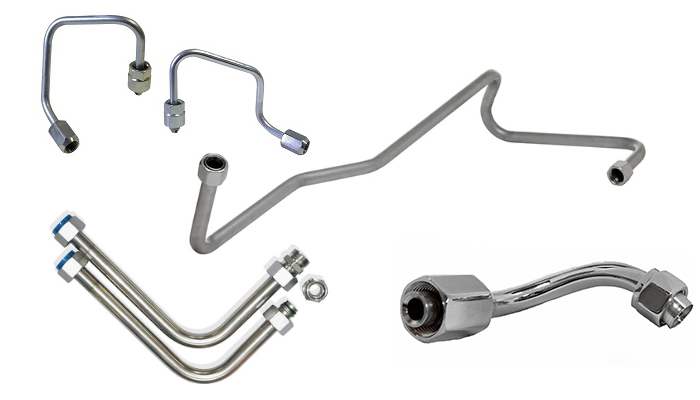

With a focus on delivering highly decorative bent tubing and tubular products, an emphasis is placed on delivering precise, clean radius bends ready for polishing and/or chrome plating.

Tube Bending Capabilities:

- Tubes Sizes from 0.25 inch Outside Diameter to 3 inch outside diameter.

- Multi-Radius Tube Bending.

- One piece, continuous loop (full radius) Tubing Bends.

- Compound Tube Bending.

- Length up to 10 feet.

- Bend radius from 0.5 inch to 12 inch.

- Tube Bends Include CNC Rotary or Manual Rotary Arm Mandrel Tube Bending, Compression And Ram Tube Bending, Three-Wheel Roll Bending, Double Headed Draw Bending, and Interpolation Bending.

|